The KNeW Process® is truly sustainable.

Water and fertilizer are both necessary to grow food and sustain life. The KNeW Process creates both fresh water and fertilizer and uses them to grow food and support nearby communities.

Both process outputs are returned to the earth, making the KNeW Process a truly sustainable industrial process.

The KNeW Process® is unique not only for its water treatment process, but for the way it creates fertilizer and plant nutrient products.

The KNeW Process® is unique not only for its water treatment process, but for the way it creates fertilizer and plant nutrient products.

Valuable products such as gypsum, ammonium sulfate, sodium chloride, dolomite and perhaps the most valuable of all - potassium nitrate - are extracted from the KNeW Process. These products can be used to generate additional revenue streams from marketing and distribution and can be used to amend soil for agriculture, returning the natural elements back to their source.

With other treatment processes, environmentally harmful sodium is returned to the ground or the water source in the form of brine discharge streams. The KNeW Process removes all sodium and isolates it in various beneficial compounds.

The KNeW Solution - A Complete Solution

According to Ruth Cairnie, Shell’s executive vice president for strategy and planning, “In the water-energy-food stress nexus, you have quite important linkages.” “You need water to develop energy. You need energy to treat and to transport water. You need energy and water to produce food. So, it’s a recognition that you need to look at all of these issues in a joined-up way. Because if you try to find solutions for just one of the issues you’ll find unintended consequences, perhaps making the others more of a problem.”

By Shell’s reckoning, by 2030 the world will need 30 percent more water, 40 percent more energy, and 50 percent more food than today.

The KNeW Process is different than other desalination processes because it converts brackish water into clean, fresh water, while also generating fertilizers and other valuable by-products.

As Shell and other scientific bodies have reported, food is the next part of the stress nexus, and KNeW has a process to address the concern.

As Shell and other scientific bodies have reported, food is the next part of the stress nexus, and KNeW has a process to address the concern.

Potassium Nitrate and other KNeW Process products can be returned to the soil through "FERTIGATION" - a process that combines irrigation and fertilization. By returning potassium nitrate to the soil, it creates a perpetual water-food-fertilizer cycle that is uniquely sustainable.

The KNeW Company is also well-positioned to facilitate "Cities of the Future" and vertical agriculture, where water is used to support local communities as well as agriculture in crops and greenhouses, while the fertilizer and other products are used to generate revenue and increase the yield and quality of the food grown.

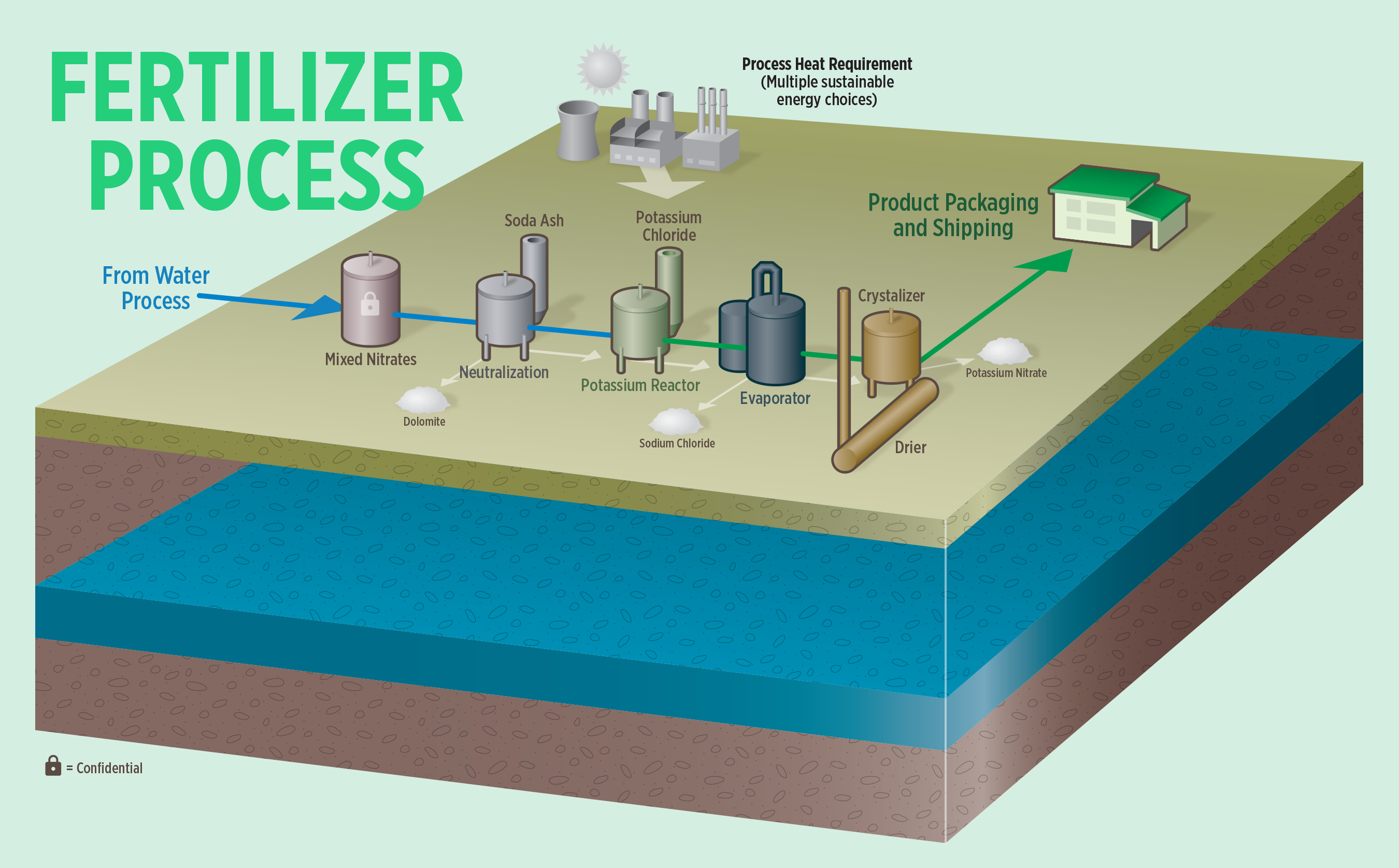

How the KNeW Process® Fertilizer Works

-

Mixed nitrates from the KNeW Water Process are stored and treated, producing dolomite.

-

Soda Ash and Potassium Chloride are introduced to neutralize and isolate the nitrates.

-

Through an evaporation process, Sodium Chloride is extracted.

-

The remaining materials are crystallized and dried, producing pure Potassium Nitrate.

-

The revenue generated from by-products of the process covers operation costs and can even generate a reasonable profit.

-

The process creates jobs for low-skilled workers in economically depressed regions.

References and Resources

For technical information information, please contact us.